Experience

Blanking Line Controls Upgrade

Phased Controls Upgrade Installation

CDSL provides installation solutions that allow our customers to tackle the projects that get put on the back burner due to the complexity of the install and the duration of the downtime.

Challenge

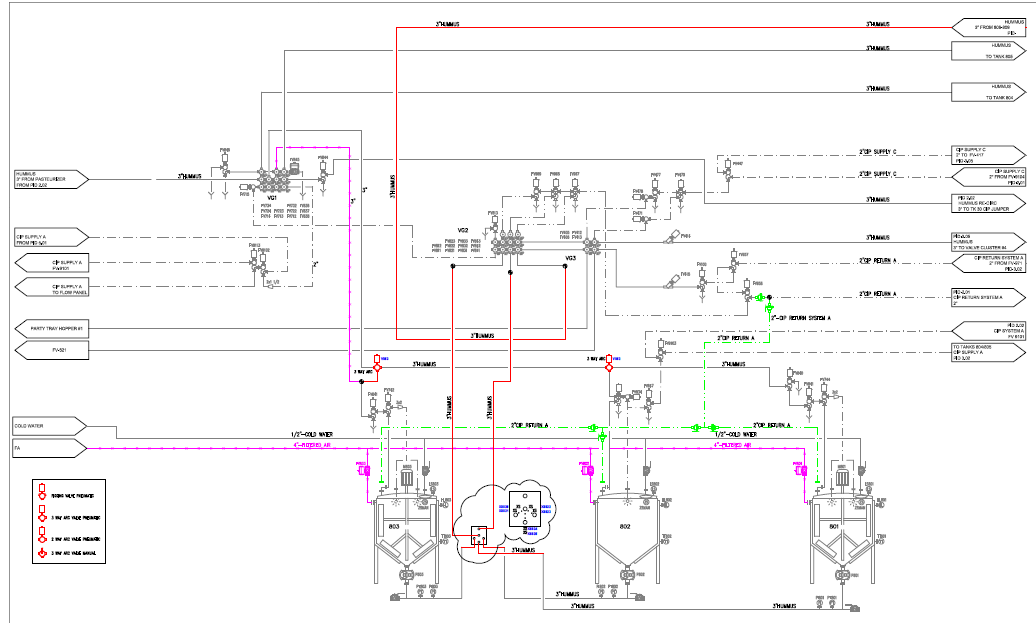

The customer requested a controls upgrade for a large portion of an existing steel line. The controls upgrade included replacing the existing controller with a safety controller and upgrading all associated safeties. The large horsepower major drives would be replaced for this project as well. Finally, many devices (smaller horsepower minor drives, remote I/O rack adapters, encoders, HMI units, etc.) would be replaced to eliminate multiple field bus protocols and standardize on Ethernet communications. The challenge for this project lied in the fact that installation downtime came at a premium and the line was old and had many updates over the years that were not always documented. To accomplish our client’s goal, we decided to proceed with a phased installation and start-up. The first phase included replacing the controller with a safety PLC and installing new remote safety I/O racks to help simplify the safety system for the line. This change in safety architecture helped eliminate over one hundred and fifty relays that were being used for line safety. The next phase involved replacing the obsolete large horsepower major drives. Using the safe-off function of the new drives and digital magnetic encoders we were able to eliminate the old safety contactors and analog tachometers. The final phase was used to eliminate the different field bus protocols that were being utilized and unify the entire controls system on one common Ethernet network.

This phased approach to installation and startup allowed us to complete the larger task at hand in a way that minimized downtime while maximizing our customer’s comfort level with the more manageable mini projects.

Value

Efficient installation solutions can make the difference when deciding whether to proceed with a project or not. Frequently, customers tell us about projects they would like to tackle, yet downtime is the limiting factor. Some facilities run hard to keep up with demand, making even the smallest of upgrades difficult. Basing our design strategy on the most efficient installation scenario and employing pre-built hardware solutions along with multi-phased installations we have been able to assist our customers in tackling their limited downtime projects.